SERVICE BULLETINS

LEGAL NOTICE - Airworthiness - Liability - warranty

Service Bulletins contain service requirements and instructions that are very important to flight safety and must be addressed, complied with, or accomplished before continued flight operations.

A “Service Bulletin“ is the equivalent of an “AD“ (Airworthiness Directive) on a Certified Aircraft. In the Experimental Regulations, no channel exists for AD’s, as such we call them Service Bulletins. These items are considered MANDATORY airworthiness items that should be fixed according to the Service Bulletin information.

A Service Letter is either a suggested change or designed as an assistant to the owner for an area where multiple difficulties arise.

Please use all guidelines and general safety measures for the installation of your engine. Viking is not responsible for individual engine installations nor workmanship of an individual.

The use of non-genuine/unauthorized parts and/or unapproved modifications fitted to any Viking Aircraft Engines constitutes a modification and/or alteration and as such all warranties express or implied, to the extent permitted by law, are voided. A product should be maintained in accordance with the requirements of the manufacturer, meets approved type design and has not been modified unless approved by the manufacturer.

Viking Aircraft Engines does not warrant or accept liability for any damage or malfunction caused by non-genuine/unauthorized parts and/or unapproved modifications fitted to any Viking Aircraft Engine (and any subsequent damage, including damage or malfunctions to associated parts or systems).

Viking Aircraft Engines does not warrant or accept liability for any damage or malfunction caused by failure to comply with Service Bulletins and/or Service Letters, lack of maintenance, including, but not limited to, the failure to follow recommended maintenance procedures, types of lubrications and/or fuels and use instructions as set forth in the Engine Maintenance Manuals, Aircraft Technical Manuals and Propeller Manuals.

The installation of non-genuine/unauthorized parts and/or unapproved modifications to any Viking Aircraft Engine constitutes a complete and total waiver to the extent permitted by law of any and all rights the operator may have had to hold Viking Aircraft Engines responsible or liable for the malfunction or failure of such a non-genuine/unauthorized part and or unapproved modification.

To the extent permitted by law, the owner, operator, overhaul facility and/or maintainer responsible for installation of non-genuine/unauthorized parts and/or unapproved modifications to any Viking Aircraft Engine shall bear the responsibility and liability for any damages of whatever nature, injury or death arising from any malfunction or failure of such non genuine/unauthorized and/or unapproved modification.

A non-genuine/unauthorized part and/or unapproved modification is classed as any product that is a parallel, imitation, salvaged, counterfeit and/or aftermarket item that has not been manufactured and/or sourced directly from Viking Aircraft Engines or can be traced back as supplied to an authorized dealer direct from Viking Aircraft Engines.

The use of a different ECU or altered ECU is strictly prohibited as it changes the operation and safety of the engine.

The use of a cowling design not from Viking, is not under warranty. Adequate cooling and flow is fully tested with our setup, any type of overheating due to the use of own/another design could cause overheating and long lasting damage.

The warranties are also VOID on any engine or accessory which has been operated contrary to corresponding Installation, Operating and Maintenance procedures or which in Vikings sole opinion has been subjected to misuse, neglect, improper installation, corrosion, foreign material ingestion, accident, the use of improper oil, fuel or non genuine Viking replacement parts. The warranties are also VOID on any engine or accessory (including propeller flange extensions) not designed or approved in writing by Viking has been used.

With the use of any Lithium battery, due to their instability and unpredictability, especially those with a Battery Management System - warranty will not be valid.

Viking will not process or honor warranty claims on delinquent accounts.

ALL ENGINES

Gear oil and gear oil temperatures

All 3 gear - gearboxes used on Viking engines should use 8 ounces of Mobile One 75W-90 or 75W-140 gear oil to ensure proper lubrication of all internal areas of the gearboxes. Gearboxes with a sight glass measure 5 ounces to the top of the glass / visible area. You would need 3 additional ounces on top of this for a total of 8 ounces.

With 8 ounces of gear oil, oil can leak out of the gearbox vent. It is best to install a catch tank on all systems.

Be sure to monitor normal temperatures; if for any reason you see an increase in average trends, please contact Viking. Gearbox temperatures should not typically exceed 170 Fahrenheit. There might be instances for the temperature to be much higher; such as, climbs, lack of cooling, pusher configurations. The main point is to monitor trends, as in, the gearbox suddenly running 20 degrees hotter than in the past etc.

100LL Fuel

When using 100LL fuel in your aircraft, over time there will be lead buildup on the exhaust valve stems, causing loss of compression. It is recommended to use auto fuel. With 100 LL the use of a lead scavenger is REQUIRED, TCP or Decalin. Once your engine has lost compression due to not using the required TCP or Decalin, there is no going back and engine disassembly is required to fully remove the lead. The lead problem is not unique to just Viking, other engines such as UL, Rotax, etc. have identical problems. In fact, it is not really a problem, you just use the additive.

Powered Parachutes Using One Pump and Battery

Typical engine installations recommend the use of two fuel pumps and two batteries. This is not standard application, there are certain requirements that need to take place if continued.

Upgrade the system to a dual setup

Replace the pump every 100 hours

Fuel flow test every 25 hours

Installation of fuel pre-filters

All header tanks, containing our in-tank fuel pumps are equipped with small filters built into the pumps. These are not adequate over time, and therefore external pre-filters, available from Viking, must be installed to ensure proper fuel flow is maintained. To verify proper fuel flow, disconnect the fuel hose on the engine and place it in a measuring cup. With the engine off, engage one fuel pump at a time. The flow should be approximately one ounce per second. Normally the test is done over a 15 second period so 12 - 18 ounces should be expected. This test should be completed at every yearly condition inspection.

Fuel Flow

Please be sure to check required fuel flow, especially if pre-filters are not installed as required by Viking. You should have results that equate to 2 Quarts/Minute. If you have questions on how to perform this test, please email or call us.

The procedure is :

Make sure fuel pumps are off.

With a rag over the quick disconnect or the banjo fitting, located at the end of the rubber fuel line at the high pressure pump on the engine, remove the connector/fitting from the pump.

Insert the end of this hose into a calibrated container and have a helper turn the fuel pump on for exactly 1 minute.

Results should be approximately 2 quarts.

ALL ENGINES WITH PUMPS THAT ARE MOUNTED FROM THE BOTTOM, NEED TO HAVE THIS PRE-FILTER REMOVED

Trimming of the Exhaust

The provided exhaust pipe is usually too long, it should be trimmed so it sticks out of the cowling approximately two inches to avoid propeller pulses from damaging the pipe.

Prop Strike

In the instance you have a prop strike, the gearbox must come back to Viking for inspection, and the torsion damper and centering bushing must be replaced

VIKING 90 SERVICE BULLETINS

There are currently no active service bulletins for the Viking 90

VIKING 110 SERVICE BULLETINS

The Viking 110 Installation and Operations Manual can be found HERE

The video is to be used in conjunction with the listed Service Bulletins below

Viking 110 mandatory flywheel upgrade

All Viking 110 engines with aluminum flywheels (gold anodized or aluminum colored) should be replaced with the latest steel flywheel.

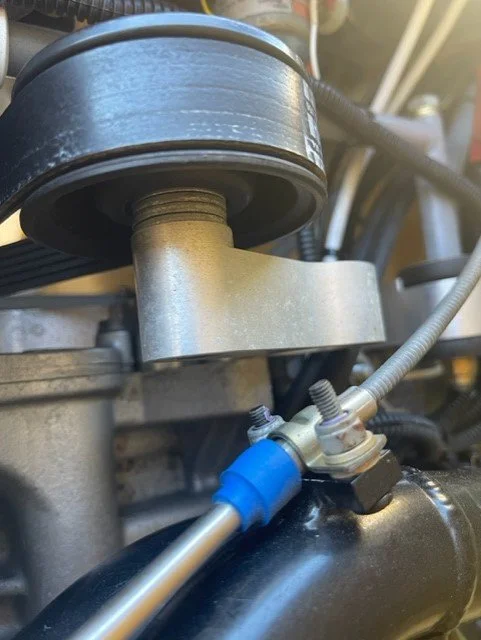

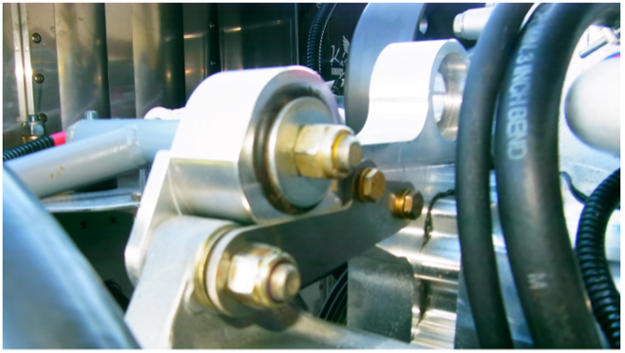

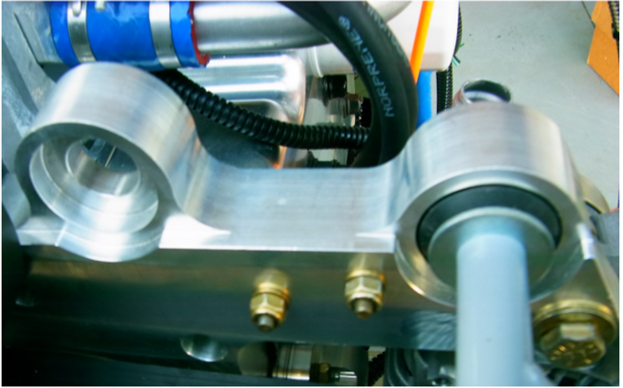

VIKING 110 MANDATORY IDLER PULLEY UPGRADE

Be sure the alternator belt idler pulley on the Viking 110 is made from steel. Test it with a magnet. The original aluminum pulley with “Viking Aircraft Engines engraved should not be used.” The upgraded pulley is available from Viking. Can be purchased here: Amazon.com: Gates 36026 DriveAlign Belt Drive Idler/Tensioner Pulley : Automotive

Viking 110 input gear update

Some early 110 gearboxes have an input gear with more end play than later gearboxes. To inspect for this use one of the following methods.

Grab one propeller blade while viewing the drive coupler. Rotate the propeller back and forth to see if these parts move in/out of the gearbox.

Use a pry bar and gently pry the coupler towards and away from the gearbox.

You are looking for roughly 0.040 (slightly less than 1/16) of end play to have this “condition” The reason for the inspection is to prevent the drive coupling from physically hitting the back of the gearbox, so also inspect for scraping parts that might indicate such.

It can be inspected yearly, or sent to Viking for a gear replacement

Viking 110 single ear alternator attach upgrade

There is an additional alternator support add-on bracket for Viking 110 engines equipped with a single top attach point. The additional bracket is available from Viking. Just bolt it to the original alternator top mount, center it on the machined housing, drill 2 holes and install AN-3 bolts of the correct length.

Viking 110 Coolant Hose Routing

If you have a Viking 110, where the coolant hoses are routed through the gearbox area and the flywheel, please ensure to route it in a different area. This will avoid something happening to the coolant lines, if something were to happen to the gearbox/prop strike so forth and vice versa.

Viking 110 OIL PICKUP HOSE

There has been an instance of the top mounted oil pickup tube fracturing and falling into the oil tank. Naturally, when this happens oil pressure is lost. Because all tanks were made the same way, and there has already been an update prior, to move the oil pickup to the bottom of the tank in order to increase suction, this now becomes and mandatory change. No Viking 110 Engines should fly with a top mounted oil pickup hose after 06/05/2018.

This picture shows the best oil pickup system for the Viking 110 engine. Some engines already have this but might use 1/2" hose, rather than a 5/8 hose and fittings. This particular engine can maintain 55-70 psi of oil pressure.

No 90 degree fittings if possible. 3/8 NPT threads. 5/8 hose barb. 5/8 hose rated for oil and suction.

Example of the best oil tank system: The oil pickup tube should be of the ridged teflon type so it can take the heat and not collapse under suction.

Viking 110 wiring upgrade

Change wiring to match the current wiring diagram for the Viking 130.

Remove ECU select switch in order to operate on a single computer only. Do this by locating the select switch on the panel, remove the three wires labeled; ECU 1, ECU 2 and SELECT. Disregard and tape the ECU 2 wire. Solder ECU 1 and SELECT together and protect with shrink tubing. If done correctly, the engine will start and run normally and the TAC (RPM) will be working.

The reason for this change is several instances of intermittent operation between ECU 1 and ECU 2 with zero failures of either one.

Locate these wires

Cap and solder as shown.

Viking 110 Valve Adjustment

VIKING 130 RECOMMENDED UPGRADES ARE ALREADY IMPLEMENTED ON 2023 ENGINES FORWARD

Update to Roller bearings in gearbox. This will increase the life of the gearbox and is highly recommended.

All engine mounts now incorporate a right offset to help counter torque.

ECU software continues to improve, and updates are available.

All fuel injection hose shipped is now using a T2 or above 225 psi rating. SAE 30R14T2 or Gates 4219BF

Heater mounting now recommend extending hoses into the cabin about 6” to make service work easier.

Engines shipped after 2/11/23 have the bypass hose between the coolant exit of the cylinder head and the Thermostat plugged with a 14mm stainless steel dowel pin. stainless dowel pin. This provides more stable thermostat operation and higher engine temperatures in the winter. Combine this with a 1/4” hole in the thermostat, instead of the jiggle pin. Test after modifying on the ground for proper thermostat operation after air is removed from the system.

Conical Rubber engine mount internal spacing tubes are now 1/4” longer to prevent cracking at the rubber edges.

All engines now use a 0-psi cooling system and no pressure cap. To remove pressure from an existing system, the bottom rubber sealing disk from the radiator cap is removed. This requires a larger catch tank such as this one: Dorman 603-001.

Optional weight saving exhaust system available. Save 4 lbs

Optional weight saving intake system available. Save 4 lbs

Optional weight saving gearbox available. Save 4 lbs

VIKING 130 SERVICE BULLETINS

Viking 110/130 Flywheel COUPLING update

The batch of parts distributed are recalled and replaced by a heavier duty part. Even though there has never been a failure, we do not take any chances. The part is already in use on the 180 hp turbo engine and has considerable testing already completed. It will fit the 110 and 130 engines directly. Anyone that has a part like this picture it should be replaced. No engines should be flying after 7/17/2017 unless the flywheel drive disk looks like the one in the picture. Update: 2023 - There is now a heavier duty triangular drive coupling used. It does not have the indents as shown in the “old, recalled flywheel coupling.” picture.

OLD RECALLED FLYWHEEL COUPLING

NEW UPDATED FLYWHEEL COUPLING

Viking 130 fuel bleed orifice

A 0.010 orifice install to bleed possible excess fuel pressure from fuel lines while aircraft is parked. This can happen if pressure leaks by the regulator needle of the high pressure engine driven pump and into the aircraft fuel system. Pressure could build to over 100+ psi since the rail pressure is 2200 psi in the stainless steel injector rail. Please call if more information is needed.

Exhaust Baffle

Exhaust Baffle

The exhaust system on the left was used on the Viking 130 until 2023. The exhaust on the right was used thereafter and is current. The earlier exhaust used a ceramic honeycomb baffle insert for muffling. Overtime this can deteriorate and must no longer be used.

Viking can remove this and install a metal baffle to adhere to the service bulletin. Alternatively, the later style can also be installed.

Exhaust Brace With Spring

The exhausts must have a spring attachment as shown below to help with any cracking issues. It will crack without this spring. This also takes the place of any other bracing used previously.

Viking 130 ecu and wire harness updates

If you have not had your ECU updated since January of 2018 - YOU MUST have it done prior to flying. We do not want anyone flying unless this has been completed.

Simply return your ECU to Viking at:

735 S. Airpark Rd. C3

Edgewater, Florida 32132

There is no charge, just include return shipping. If you have any questions or your not sure yours has been completed you can email Alissa@vikingaircraftengines.com

Viking view wire

Some have mistaken the Viking View (Green/White) wire as a negative ground. If this wire is grounded you will disrupt the proper operation of the ECU. If you DO NOT have a Viking View instrument, this wire must be capped off and not used. If you DO have a Viking View, simply use for the Viking View ground as instructed with instrument. That means, connect to Viking View ground wire. It does not mean to connect the wire to any ground, it IS teh ground for the Viking View.

if ecu power is shorted to ground

We have had a few circumstances where installers have shorted their ECU power to ground, when this happens you burn up the ECU making it unrepairable and likely damaging other 12V components on the engine. In order to protect the ECU during installation of your electrical system, it is suggested that the ECU power wires are protected with electrical tape and installed after other electrical work is completed. You might also use a 1 amp fuse (increase up to 5 amp if it keeps blowing) between the ECU power leads and the main power buss the first time power is applied (this is just a quick test to verify that there is no short and obviously should not be left in place, the ECU should remain unfused as shown in the diagram for normal operation)

Except for emergency situations you should not run the system without batteries engaged.

Do not crank the engine without the starter relay or it could introduce a large spike into the system damaging the ECU.

A symptom of a burnt up ECU is a strong electrical smell from the ECU enclosure.

You will have to replace the following on the engine if power is shorted to ground:

Your ECU

Crank Sensor

CAM Sensor

Variable Valve Timing Solenoid

Variable Valve Lift Solenoid

Coils (4)

The cost of a new ECU is $1500.00

Cost for additional items: $815.00 (subject to change) These items MUST be replaced.

None of this is to indicate that the ECU is fragile in anyway. It is just like any other electrical device where voltage reversal is not acceptable. We feel the lack of fuses increase the overall safety.

Removal and Re-Installation of Gearbox

This should only be done if consulted with Viking. A new centering bushing is 100% required when re-installing.

Viking 130 and Viking Turbo Valve Adjustment

Be sure to just “check” the valve lash without loosening any hardware. Nine times out of ten you don’t actually have to adjust anything.

VIKING 150 SERVICE BULLETINS

VIKING 180T/195T SERVICE BULLETINS

If not already done, the knock sensor must be installed. Please contact Alissa for the kit if needed.

Intercooler Mounting

Active as of 03/01/2022. Any engines sent after this date will not need to comply, as it has already been done on your engine.

The warranties are also VOID on any engine or accessory which has been operated contrary to corresponding Installation, Operating and Maintenance procedures or which in Vikings sole opinion has been subjected to misuse, neglect, improper installation, corrosion, foreign material ingestion, accident, the use of improper oil, fuel or non genuine Viking replacement parts. The warranties are also VOID on any engine or accessory (including propeller flange exten-sions) not designed or approved in writing by Viking has been used.