Zenith 750 Landing Gear Bracket Set

Zenith 750 Landing Gear Bracket Set

Holes for brake line routing and tapped holes for Adel clamps.

Information below provided by a customer experience, Jonathan Fay - his Blog is here: My 750 Cruzer – Building an Airplane with my Son (wordpress.com)

It’s been a while since I have made a post. Been flying a lot and maintenance has been routine and I am getting close to 300 hours on the Hobbs meter and time for 4-year anniversary condition inspection.

Some of the things I have been tracking that needed addressing have been the main landing gear retention bracket, freshening up the lower fairings on the struts/gear legs and dealing with the muffler bearings.

4 years of backcountry landings on gravel, grass and pavement along with the taller gear, bigger tires and higher gross weight have taken their toll on the landing gear retention brackets. These were the one weak spot I had not addressed. Roger from Zenith had sold me some raw thicker brackets but I had never machined them and installed them. I did not have plans for how to cut and drill them, so I procrastinated and kept a watch on the current ones. Putting the fairings on improved the look, but also made it harder to monitor the slow demise of the parts. You could look underneath with a crawler, but it was harder to inspect during pre-flight.

Make it stand out

The Zenith design works fine for small tires, the stock brakes and short gear, but with the extras stress from the leverage of the tall gear and big breaks, you need more to fight the torque. Viking had seen created similar replacement parts for people who stress their airplanes more than normal like the steel bungee for the nose. They came up with an enhanced machined part for replacing the factory retention brackets with an engineered CNC part instead of a machined L bracket. This was a much stronger solution. The old one would bend and twist under the load and could eventually fail. I am wondering if the new one would just overload and then transfer the damage to the fuselage, or snap first. I am not sure, but I will keep a watch on that area.

The part is a work of art. CNCed and then powder coated. It is light but looks very strong and unlikely to bend like the L-bracket version. It also comes with new bolts, washers and retention clips with AN-3 hardware to keep the bolts from rotating.

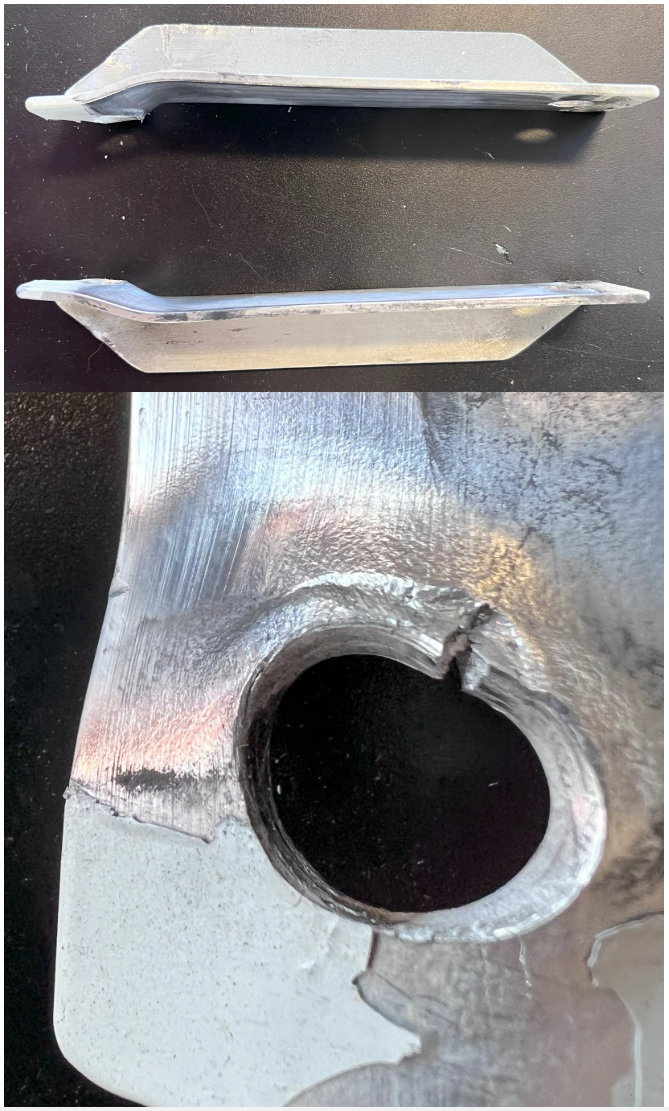

I removed the existing fairings and the full extent of the need for the new parts was clear. When removed both parts were severality deformed by stress, and one was developing a tear. Another hard landing might have caused a total failure, or maybe 10 more? Hard to know. This has had hundreds of off-field landings with 4″ more leverage, and double brakes. It has lived a hard life.

I chalked the wheels and did one side at a time and did not have to put the airplane on a lift. The installation of the new parts was smooth but required deliberate, careful sliding over to make sure they went on evenly and did not bind on the threads. I made sure there was a bit of play in the gear to bend as demonstrated in the Zenith installation guides. I will have to monitor the braking and bounce to make sure they are set correctly.